CNC machining is a process used for manufacturing aerospace parts because the process is capable of achieving extremely tight tolerances. Read on to see what you need to know about the key role CNC machining plays in aerospace machined components.

The aerospace industry is renowned for the highest quality standards, rigorous testing practices, and strict regulatory requirements. Aerospace machined components need to be a combination of high performance, high velocity, function at very high altitude, or work at extreme temperatures at either end of the spectrum. Thus, any manufactured component needs to withstand these elements.

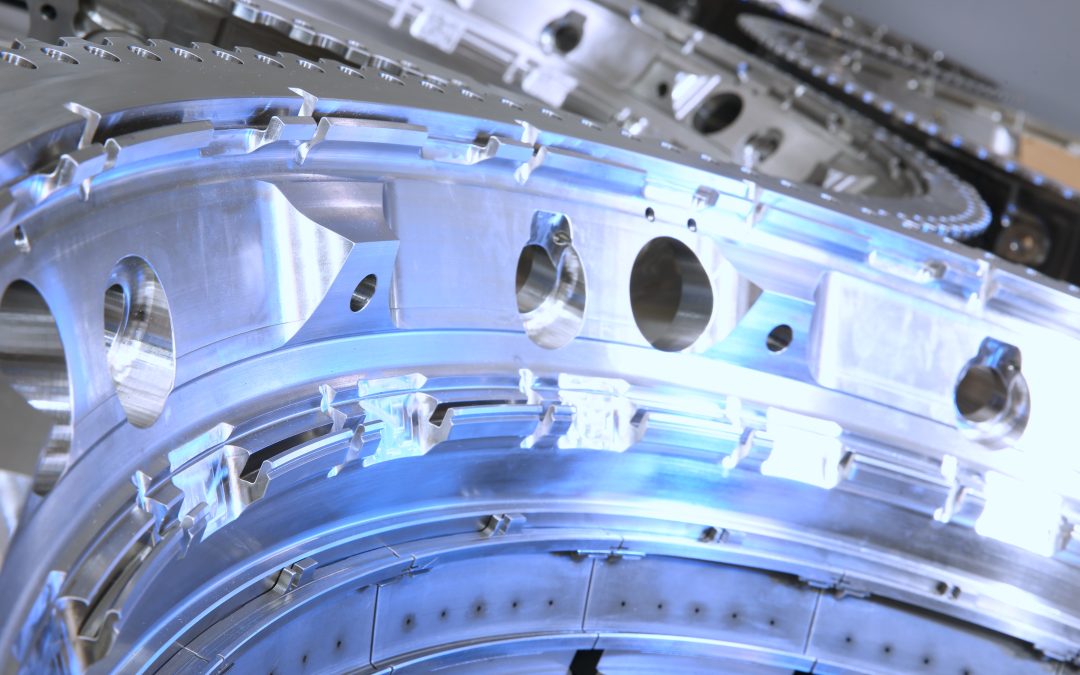

CNC machining is appropriate for use in the aerospace industry and other demanding sectors due to its accuracy and repeatability; the aerospace industry demands extreme levels of precision. This increase in precision offered as a second process allows a component to be manufactured to the tight technical demands over above primary process such as rolling, casting and forging. The Secondary machining process enables components to be manufactured repeatably while meeting fit form and function

With the many relevant regulatory requirements, testing criteria, and functional requirements at work in modern aerospace manufacturing, part precision is very important. The way aircraft are produced and assembled is precise, so inconsistencies and flaws can have wide-reaching negative effects.

CNC machining services for the manufacture of aerospace parts

CNC machining is a method of manufacturing where pre-programed computer software controls the movement of tools, which in turn manufacture a specific component. It is used to cut and shape pre-existing material into brand new, purpose designed component. This manufacturing process increases the amount of repeatability that is possible in a production process, thus being a cost and time effective manufacturing solution.

CNC Machining Services from AML

AML offers in-house adaptive machining algorithms to achieve the tightest of tolerances. We have the capability to manufacture parts for the aerospace industry in a range of specialist materials including titanium, nickel-based superalloys, and softer alloys inc. aluminium. Our CNC machining capabilities are recognised in the industry.

Aerospace remains a significant industry for both Global and UK manufacturing, with ever increasing trends towards light weighting and innovative technologies supporting greener flying patterns. Precision components machining remains a foundation corner stone of the industry, with ever more complex geometries and materials requiring innovative manufacturing solutions. AML has continued to position itself in this market sector over the years, continually improving its machining services to meet these challenges.

AML is an advanced manufacturing supplier specialising in the development of manufacturing solutions and production services for a number of prestigious blue-chip clients. AML is now recognised as a market leader in delivering flexible manufacturing capability at the leading edge of machining technologies and efficiencies, with particular expertise in aerospace, defence and energy components.

Recent Comments