UKAEA awards £3.1million of contracts to accelerate the growth of UK’s fusion industry

AML Sheffield working with Castings Technology International is extremely proud to be a member of one of the 18 consortiums to have secured a contract with the United Kingdom Atomic Energy Authority to demonstrate how their innovative technologies and proposed solutions can help make fusion energy a commercial reality.

The organisations will focus on overcoming specific technical and physical challenges.

The contracts – feasibility studies from £50,000 up to £200,000 – are funded by the UKAEA’s ‘Fusion Industry Programme’ and awarded through the UK Government platform ‘Small Business Research Initiative’. The latest contracts are the second part of the Fusion Industry Programme, following the first cycle of the Fusion Industry Programme in 2021.

The projects aim to tackle specific challenges linked to the commercialisation of fusion energy, from novel fusion materials and manufacturing techniques through to innovative heating and cooling systems, all needed for future fusion powerplants.

Tim Bestwick, UKAEA’s Chief Technology Officer, said: “In the past 12 months we have seen significant advances both in the UK and globally that demonstrate the potential for fusion energy to be a safe, low-carbon and sustainable part of the world’s future energy supply. However, there are a number of significant technical challenges to address for fusion energy to realise its potential. The Fusion Industry Programme is helping engage organisations and industrial partners to stimulate innovation and address these important challenges.”

The Fusion Industry Programme is part of the Government’s £484 million support package for UK research, announced last year. The Programme was allocated £42.1 million as part of this package to stimulate innovation and to accelerate the development of the fusion industry.

Contracts have been awarded to start-ups, small-medium enterprises, established companies, and academia, with six of the eighteen organisations receiving funding through the Fusion Industry Programme for the first time (see below for the full list).

As a growing industry, knowledge transfer from other technical and engineering sectors is vitally important to the fusion industry. Collaborating with wider industry allows a collective approach to tackling climate change issues and faster access to energy security.

The Fusion Industry Programme was launched in 2021 to drive long-term economic growth by developing technology and skills that can both support domestic programmes and be exported globally.

Fusion energy is sometimes described as the ultimate energy source, based on the same processes that power the sun and stars. It has the potential to provide ‘baseload’ power, complementing renewable and other low carbon energy sources.

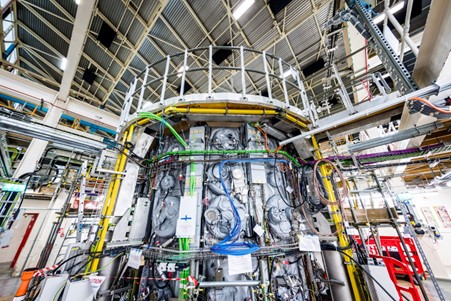

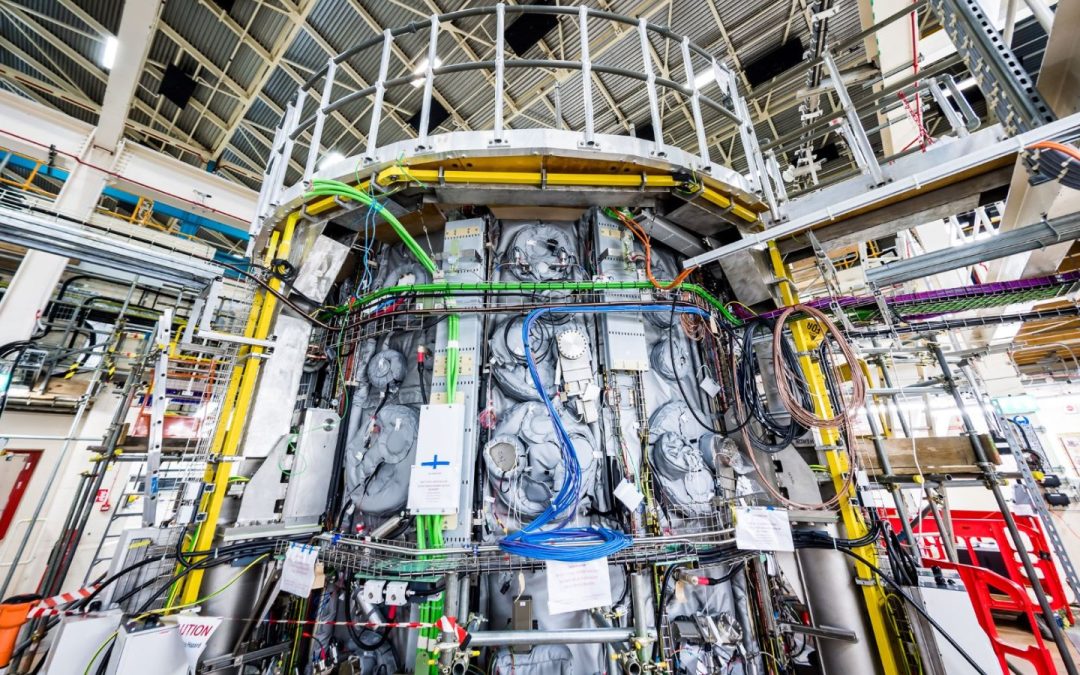

MAST-U A fusion energy machine at UKAEA’s Culham Campus vital for the delivery of fusion powerplants Credit SMD Photography

About Fusion Industry Programme:

The contracts have been awarded as part of the second cycle of funding from the Fusion Industry Programme’s Challenge scheme, which engages and supports UK businesses to overcome the important technical challenges in fusion.

This funding follows the successful awarding of contracts for the first cycle of the Fusion Industry Programme, announced in 2021.

Successful organisations will now work to demonstrate the feasibility of their technologies and techniques. The most innovative solutions will be offered a chance to develop demonstrators during Phase Two of the scheme, with contracts of between £1m-£3m. Feasibility studies will be presented and selections for phase two will commence in the coming months.

Full list of organisations awarded contracts under Cycle Two of the Fusion Industry Programme.

Driving up fusion power plant performance with innovative heating and cooling systems.

| Organisation | Project Title |

| CAL GAVIN Limited | Critical Heat Flux shifter device (CHF-shifter insert) |

| TWI Limited | CoreFlow for simplifying fusion reactor thermal

management |

| IDOM (UK) Limited | Jet impingement technology transfer |

| University of Manchester | Development of Tungsten Diamond Composites for

Nuclear Fusion Applications |

Improving fusion power plant availability with novel fusion materials, technology, and manufacture

| Organisation | Project Title |

| University of Birmingham | FATHOM (Fabrication of Tungsten using HOt isostatic pressing and additive Manufacturing) |

| Full Matrix Limited | In-situ health monitoring of nuclear fusion supply pipes |

| Alloyed Limited | AMRSAF (Additively Manufactured RAFM Steels

for Applications in Fusion) |

| QDOT Technology Limited | AM+ COOL (Indirect additive manufacture for complex,

high-performance, cooling devices) |

| Astral Neutronics Limited | Tritium Breeding Materials Testing Capability with a

Novel Compact Fusion Neutron Source |

| Laser Additive Solutions Limited | AM4F (Additive Manufacturing for Non-Coolant

Components of Fusion Reactors) |

| Archer Technicoat Limited | BROCCOLi (Barrier-layers of Rare-earth Oxide

Coatings to Corrosion in Liquid-lithium) |

| Oxford Sigma | Liquid Lithium Corrosion Resistant Materials

For Breeder Blankets |

| 3-SCI Limited | Ultra High Temperature Electrical Distributed Sensing |

| Fraser-Nash Consultancy Limited | Plasma drift-orbit separation for Li enrichment |

| Castings Technology International Limited | TITAN (opTimized castIng of reduced acTivation

Alloys for fusioN) |

| Duality Quantum Photonics Limited | TRONN: Tokamak-robust optical neural networks |

Recent Comments